In our latest blog, we dive into the experiences of Rhyme's Regional Sales Managers—Hogan, Jeff, and Brad—who recently attended the Xerox Production Training at Xerox’s Headquarters in Rochester, NY. This in-depth training provided them with hands-on learning, expert insights, and a firsthand look at Xerox's cutting-edge production print technology. From advanced color capabilities and customizable software solutions to practical tools designed to enhance productivity and profitability, our team is excited to share key takeaways that will benefit Rhyme clients. Read on to discover how this training experience has strengthened Rhyme’s commitment to delivering innovative, top-tier solutions in production print.

- Can you tell us about your experience attending the Xerox Production Training at their HQ? What has stood out to you the most?

Hogan: Seeing the devices in person and in action really opened my eyes to Xerox’s diverse offerings and capabilities. It’s also great that customers have the option to visit Xerox’s facility to see live demos themselves.

Jeff: It was a very well-run training at a high-end facility, where hands-on learning made a big impact. Seeing the vibrant color range in person on real products was amazing. The overall focus is to help increase profitability for customers running print jobs.

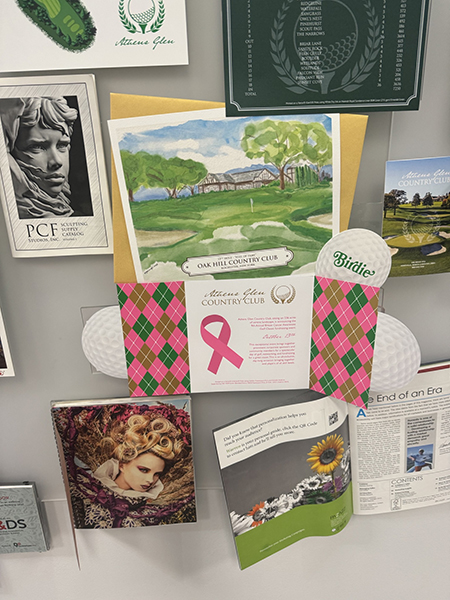

Brad: Xerox’s HQ is an impressive facility with passionate experts who bring huge value to customers. It’s also a great resource; a customer can work with their client manager to send a file to Xerox for a test print, including CMYK+ enhancements and embellishments, which Xerox then mails back for review.

- What new insights or knowledge have you gained from the training that you’re excited to bring back to Rhyme and your clients?

Hogan: Learning how to leverage XMPie for Variable Data Printing (VDP) was exciting—it’s a scalable solution that can tie in email, video, and even promotional items, offering high customization on printed products. Unlock new goals for ROI through the automation available with FreeFlow including, increase production, reduce delivery time, reduce errors, and increase cost savings. For example, creating personalized calendars is just one application of its potential. Designed to tie directly into Xerox FreeFlow.

The FreeFlow software was another highlight; it can arrange various document sizes on a single sheet to maximize paper use, reduce waste, and improve productivity. The Xerox Genesis training for designers is also invaluable for helping clients make the most of these devices. These trainings focus on fueling creative inspiration and file preparation and de-mystifying special design techniques with simple how-to steps.

- How has this training deepened your understanding of Xerox’s production print solutions? Any particular features or innovations that caught your attention?

Hogan, Jeff, & Brad: The training really brought to life the advanced capabilities of Xerox’s production devices, especially the 6-color gamut of the Iridesse. With up to seven passes, it can create unique textures, providing a standout level of versatility and visual appeal that clients will love.

- Can you share a specific moment or part of the training that really impacted you or changed your perspective on Xerox’s production capabilities?

Jeff: Seeing the Iridesse’s 6-color gamut in action and its ability to create unique textures in just one pass through the machine was incredible. No other device offers this level of quality and efficiency.

- How do you see these advancements changing the landscape for production print in the next few years?

Hogan, Jeff, & Brad: These devices are versatile enough to benefit a range of businesses beyond traditional print shops, such as universities and marketing departments. The potential for personalized, eye-catching print materials is huge.

- Can you share one or two things you’ve learned that will benefit your clients directly?

Hogan, Jeff, & Brad: Understanding how clients can use these devices as revenue generators instead of just cost items was key. Tools like Xerox’s cost estimator help clients price jobs per piece, ensuring profitability.

- How do you think this training will enhance Rhyme’s ability to offer advanced print technology solutions?

Hogan, Jeff, & Brad: With hands-on knowledge and enthusiasm, we’re better positioned to guide clients on maximizing their workflows and using these advanced tools to open new revenue streams. Our experience at Xerox allows us to share practical applications and support for clients through the whole process—from design to equipment.

- What are some key takeaways that you believe set Xerox’s production devices apart from competitors?

Hogan, Jeff, & Brad: Xerox has a unique approach to multi-color printing. While Ricoh’s 5-color process requires up to 60 minutes to change colors, Xerox’s design uses a single drum and toner unit that can be swapped out in about 10 minutes, saving significant time and cost. The Iridesse production press also features an oscillating transfer belt that reduces wear marks. When the device passes a set number of prints the machine will automatically buff the belt when the device is idle.

- How does this training position Rhyme to better serve clients looking for advanced print technology solutions?

Hogan, Jeff, & Brad: We have deeper knowledge as to the questions to ask to understand each client’s specific workflow needs, so we can suggest solutions that fit. Seeing applications firsthand has given us more insight into how these technologies create value for diverse industries.

- What advice would you give to clients or other professionals about staying up to date with advancements in production print technology?

Brad: It’s crucial to stay ahead in this space. Genesis training is a good start, and tools like personalized marketing materials can help organizations like hospitals, universities, Marketing/advertising companies, and real estate firms differentiate themselves and connect better with their audiences.

- How does participating in this type of training align with Rhyme’s mission and commitment to staying on the cutting edge of office technology?

Hogan, Jeff, & Brad: Rhyme’s commitment to a growth mindset is clear. By investing in training like this, we’re ensuring we stay ahead in technology and bring that expertise back to our clients.

This hands-on training provided Hogan, Jeff, and Brad Rhyme Regional Sales Managers with expert insights into Xerox's advanced production print technology, including enhanced color capabilities and customizable software solutions. The practical tools they gained will not only boost productivity and profitability but also reinforce Rhyme’s commitment to delivering innovative, top-tier solutions for our clients. We look forward to sharing how this training will translate into greater value for Rhyme’s customers.

Want to learn more about Xerox production print offerings? Visit our Xerox production devices page.